Inside workwear Properties

Common Issues

The large workwear industry faces many common problems in the manufacture of products.

Common Issues

Below is the list of major aftercare-related issues that workwear commonly faces.

Properties

- Color Fading and Loss of Visibility

- Loss of Flame Resistance (FR) Properties

- Chemical and Oil Stains

- Breakdown of Reflective Tape

- Loss of Waterproof and Weather-Resistant Coatings

- Deterioration of Anti-Static Properties

- Loss of Breathability

- Shrinkage and Loss of Fit

- Odor Retention

- Abrasion and Pilling

- Reduced UV Protection

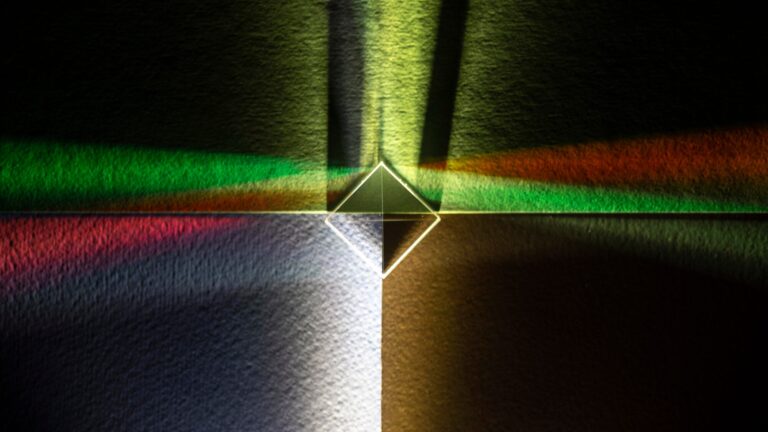

Color Fading and Loss of Visibility

Problem: Frequent washing, especially in high-visibility workwear, can cause color fading, which reduces visibility and safety compliance.

Impact: High-visibility clothing, such as EN ISO 20471 certified garments, relies on vibrant fluorescent colors to ensure worker safety.

Fading diminishes the reflective quality and can make the garment non-compliant.

Solution: Use detergents without bleach or harsh chemicals, wash at recommended temperatures, and avoid direct sunlight drying to preserve colors.

Loss of Flame Resistance (FR) Properties

Problem: Improper washing methods or use of non-compliant detergents can strip away flame-resistant (FR) coatings or treatments, compromising safety.

Impact: FR workwear in industries like welding or oil and gas must maintain its fire-resistant properties to protect against burn injuries. Fading of FR properties can make garments ineffective in high-risk environments.

Solution: Follow NFPA 2112 and EN ISO 11612 aftercare guidelines, avoiding fabric softeners and chlorine bleach, and using only FR-approved cleaning agents.

AS/NZS 4824 (Australia/New Zealand): Fire-resistant protective clothing for firefighters and emergency responders.

ISO 9185 (Global): Protection against molten metal splash for industries dealing with foundries and welding.

ASTM F1930 (USA): Manikin thermal protective performance evaluation for flash fire exposure.

Chemical and Oil Stains

Problem: Persistent stains from oils, chemicals, and grease are common in heavy industries and can degrade fabric quality over time.

Impact: Stains can weaken fabric fibers and reduce the effectiveness of chemical-resistant workwear in industries such as manufacturing and maintenance.

Solution: Pre-treat stains promptly with stain removers compatible with the fabric’s protective properties, and use industrial-grade detergents where possible..

Breakdown of Reflective Tape

Problem: Repeated washing, especially in high-heat conditions, can cause reflective tapes to crack, peel, or lose their reflectivity.

Impact: Reflective tapes are crucial in high-visibility workwear for safety in low-light environments, as required by ANSI/ISEA 107 and EN ISO 20471. Damaged tape reduces visibility and may lead to safety violations.

Solution: Use low-heat washing and drying, and avoid abrasion on reflective surfaces to extend the life of reflective tapes. Replace damaged tapes as needed.

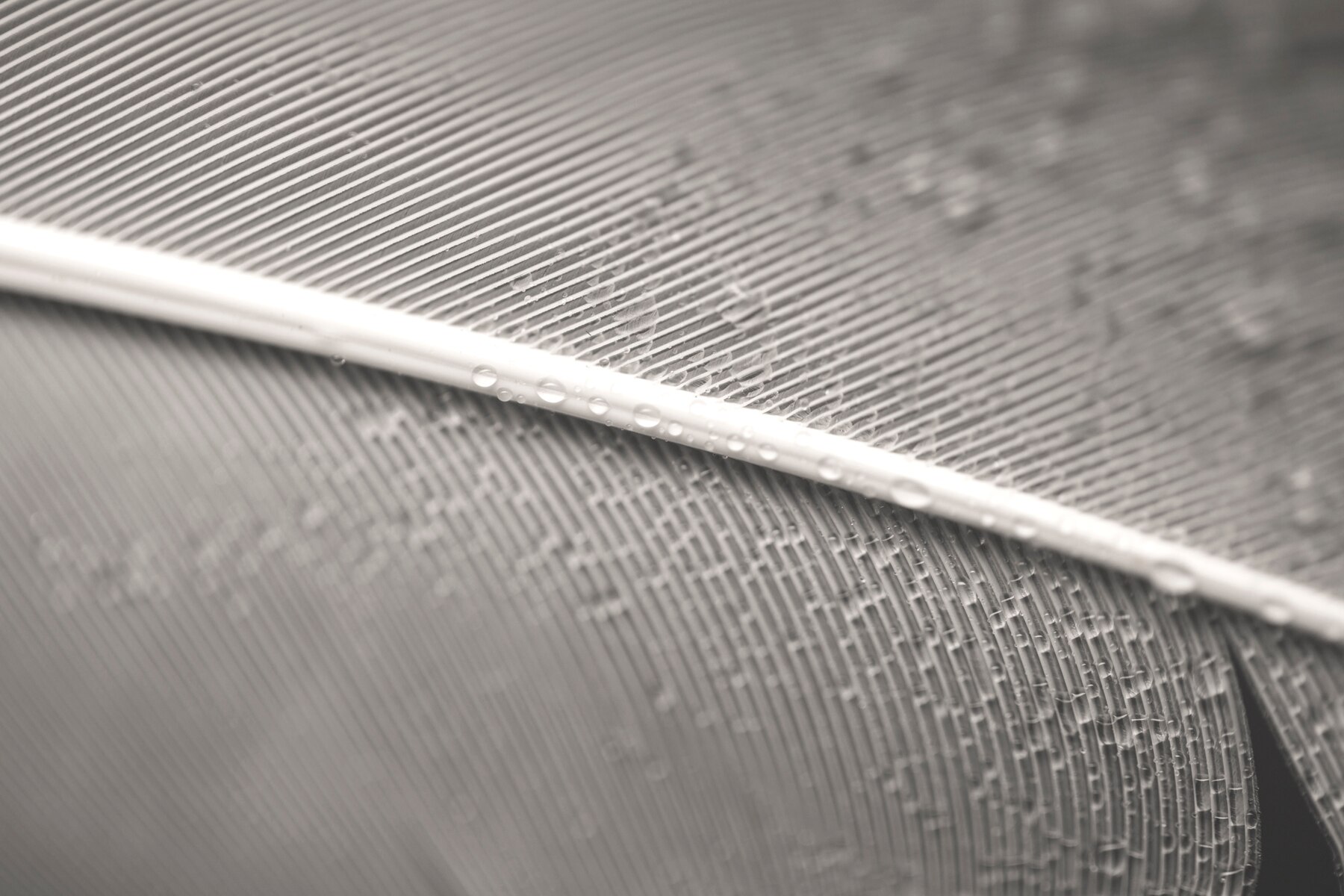

Loss of Waterproof and Weather-Resistant Coatings

Problem: Harsh detergents, high-heat drying, and frequent washing can deteriorate waterproof coatings on weather-resistant workwear.

Impact: Waterproof workwear, such as those adhering to EN 343 standards, requires durable water repellency to keep workers dry in outdoor or rainy environments. Loss of this property affects worker comfort and protection.

Solution: Reapply durable water repellent (DWR) coatings periodically and use gentle detergents without fabric softeners to maintain waterproof performance.

Deterioration of Anti-Static Properties

Problem: Improper care, such as washing with non-compliant detergents, can diminish anti-static properties required in sensitive environments.

Impact: Anti-static workwear, like that certified under EN 1149-5, is vital in industries like electronics and explosive environments to prevent static buildup. Loss of anti-static function poses risks to both equipment and safety.

Solution: Use mild, anti-static-compatible detergents and avoid high-heat drying to maintain anti-static capabilities.

Loss of Breathability

Problem: Frequent washing with fabric softeners or improper drying can clog fabric pores, reducing the breathability of the workwear.

Impact: Breathable workwear, often certified by ISO 11092 standards, is critical for worker comfort in physically demanding jobs. Reduced breathability can lead to overheating, discomfort, and decreased productivity.

Solution: Avoid fabric softeners and use detergents specifically designed for breathable fabrics to retain ventilation properties.

Shrinkage and Loss of Fit

Problem: High-heat drying or improper washing can lead to workwear shrinkage, which affects fit and comfort.

Impact: Shrinkage can make garments tight and restrictive, limiting the range of motion needed in physical jobs, and may cause discomfort or even safety issues.

Solution: Use low-temperature drying settings or air-drying methods to minimize shrinkage, following ISO 15797 laundry standards for industrial workwear.

Odor Retention

Problem: Accumulation of sweat, chemicals, and environmental odors can result in lingering smells that regular washing doesn’t fully remove.

Impact: Odor retention can affect worker comfort and confidence, especially in public-facing roles, such as healthcare and hospitality.

Solution: Use odor-neutralizing detergents and consider vinegar or baking soda additives, depending on fabric compatibility, to help eliminate persistent odors.

Abrasion and Pilling

Problem: Friction during wear and repeated washing can cause pilling and fabric abrasion, which affects the durability and appearance of workwear.

Impact: Abrasion is particularly problematic in industries requiring durable outer layers, like construction and mining. Pilling and worn surfaces reduce the garment’s professional look and its longevity.

Solution: Wash on gentle cycles, avoid rough surfaces, and use garment bags when machine-washing to protect fabric from abrasion and extend lifespan.

Reduced UV Protection

Problem: Sunlight exposure, especially when drying outdoors, and frequent washing can reduce the UV protection properties of certain fabrics.

Impact: UV-protective workwear is essential in industries with prolonged sun exposure, such as agriculture and construction. Loss of UV protection can expose workers to harmful sun rays.

Solution: Avoid prolonged sun drying and replace UV-protective garments as recommended. Use UV-safe detergents to maintain UV-blocking capabilities.